6 min read

3D Printing - Additive Manufacturing - Rapid Prototyping

Tecnon OrbiChem

:

Apr 1, 2022 8:24:26 AM

Additive manufacturing (AM) – or 3D printing – is a technique for producing solid objects by arranging particles in space via a computer-controlled process. It includes a method for fusing the particles together in an oft- intricately shaped end product.

Several methods for using compacted packages of plastic materials to spatially arrange and compact particles into objects have emerged since the 1980s.

And while various AM techniques exist today, the technology’s main premise is to build objects up layer by layer. The particles from which these layers are formed however, can be made of plastics, silicones, metals or ceramics and even concrete and cement-based materials.

3D Print History

3D printing was first commercialized by 3D Systems, which is based in South Carolina in the US. Its founder Chuck Hull described a process for ‘printing’ objects using an ultraviolet light focused, "Onto the surface of a vat filled with a liquid photopolymer," – or a light-activated resin. Hull termed the process stereolithography (SLA) in his patent application.

Soon after Hull’s innovation, Scott Crump devised a method he called fused deposition modeling (FDM) or fused filament fabrication (FFF). FDM uses thermoplastics deposited in layers, bonded by heating, to create a 3D-printed object.

During printing, a plastic filament is fed through a hot extruder nozzle. The plastic is softened to enable precise placement of the material with the print head. The melted filament is then layered in the print area to build the item. Along with his wife Lisa, Crump co-founded the company Stratasys in 1990.

The Selective Laser Sintering (SLS) technique was developed and patented in the 1980s by University of Texas mechanical engineering professor Joe Beaman and undergraduate student Carl Deckard. In this process, a solid, three-dimensional object is printed by fusing tiny particles of plastic, ceramic, or glass using heat from a high-power laser.

Source: Tecnon OrbiChem

Polyjet Process

Around the year 2000, the US/Israeli company Stratasys launched its liquid prepolymer-based Polyjet printer. The device polymerizes at spatial points by directing a UV light, or laser beam, at the prepolymer. The method Polyjet employs is also termed MultiJet printing and photopolymer jetting. Polyjet printers can mix up to three resins, which facilitates differing levels of flexibility or transparency depending on the application. Polyjet printers can use rubber-like resins in addition to rigid resins.

Stratasys’s Polyjet process uses liquid photopolymers that are fed to a head on a carriage and operate like an ink-jet printer. The inkjet head has several hundred nozzles and droplets are jetted onto a surface and then cured by UV light. After a thin layer is created, the process repeats itself by jetting additional layers until the part is fully formed.

On-Demand Carbon Composite

Source: Arevo

Silicon Valley-based startup Arevo uses technology to combine 3D printed carbon-fiber reinforced composite raw material with web-based software. The cycle's frame is made up of two-millimeter carbon-fiber filaments, with each filament itself comprising 10,000 individual strands.

A key benefit of 3D printed products that are formulated based on digital designs is that they can be customized to individual specifications and printed on demand. The bicycle went from concept to usable production in less than 18 days and it weighs less than 6kg.

Source: Tecnon OrbiChem

Materials World

The thermoplastic polymer acrylonitrile butadiene styrene (ABS) was one of the first plastics to be turned into filament for desktop 3D printers.

It was used – among other materials – by Stratasys's larger systems for filament printing and therefore, it came to be regarded as a standard material within the industry. Since ABS was already commonly available in the form of plastic welding rods, it was simple to convert into filament.

The thermoplastic polymer polylactic acid – or polylactide – (PLA) is a strong competitor. Its production involves the fermentation of a carbohydrate source such as wheat, corn, rice, and sweet potato. Being both biocompatible and compostable, it gives the 3D print feedstock portfolio a renewable option. Polypropylene filament has the advantage of creating tough plastics with high chemical heat resistance. Commonly used for packaging and storage applications, polypropylene also finds common use as the material for vehicle bumpers.

Polyamides (PA 6 and 66 blends or PA 11 and 12) in powder form are used in SLS print systems. Epoxy resins, polystyrene, and a mix of wood flour and PLA can also be used. Various reinforcements and additives can be incorporated into the polymer. Carbon or glass fiber is used to increase the rigidity and strength of the final article, while ceramic particles help in heat-induced post-curing. By adding graphene, the finished item is capable of electrical conductivity.

Liquid, Powder, or Solid?

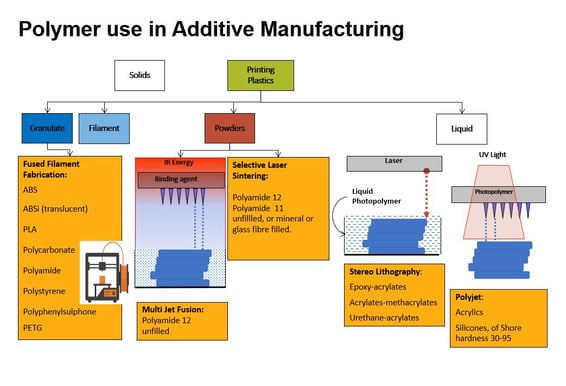

There are several techniques in which compactly-packaged plastic materials can be arranged spatially and polymerized and/or bonded together. Stereolithography apparatus (SLA) is one of the main techniques. The process requires a vat of resin and an ultraviolet laser which directs a beam at the surface of the liquid resin to trace a pattern to build parts.

The selective laser sintering (SLS) and MultiJet fusion (MJF) approaches use powders that instantly bond together after placement. Lastly, the FFF – or granulate extrusion – method relies on thermoplastic solid polymers that are melted, extruded to a nozzle unit, and deposited to form layers.

The various methods for binding the particles include the use of molten materials that congeal to form the 'glue' that fixes the item together or the use of additives that ensure the plastic material will be photocured into its shape by exposure to ultraviolet light. Alternatively, powders are melted in situ with lasers or infrared heat on fusing agents or liquids can be vulcanized into shape.

Polymer Suitability for SLS

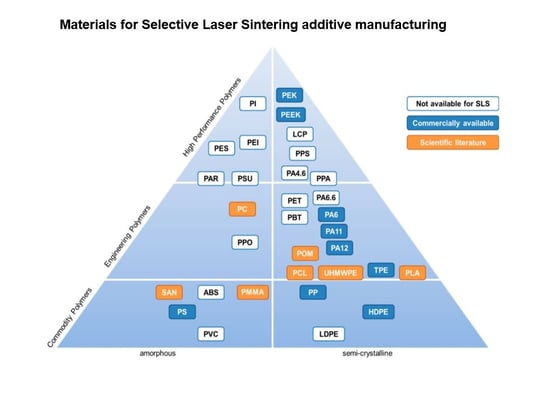

Many materials can be used to 3D print objects by the SLS method. However, as shown in the pyramid of polymer materials image below, only a limited number are commercially practicable.

A study published by the American Chemical Society's (ACS) Chemical Reviews journal in 20171 investigated materials for the Selective Laser Sintering technique.

Source: Ligon, S et al. Chem. Rev., 2017

Source: Ligon, S et al. Chem. Rev., 2017

The research team behind the study found the materials indicated in orange had been mentioned in research but were not supplied as powders for SLS.

Polyamide 12 is the most widely used material for SLS due to the combination of its ideal melting point, mechanical properties, and low water uptake. PA11 is a cheaper alternative but has poorer dimensional stability. Amorphous thermoplastics – polymethyl methacrylate, polystyrene, polycarbonate, and polysulfone – generally create objects with overly excessive porosity levels, which makes them unsuitable for use in SLS settings.

Supply Chain and Markets

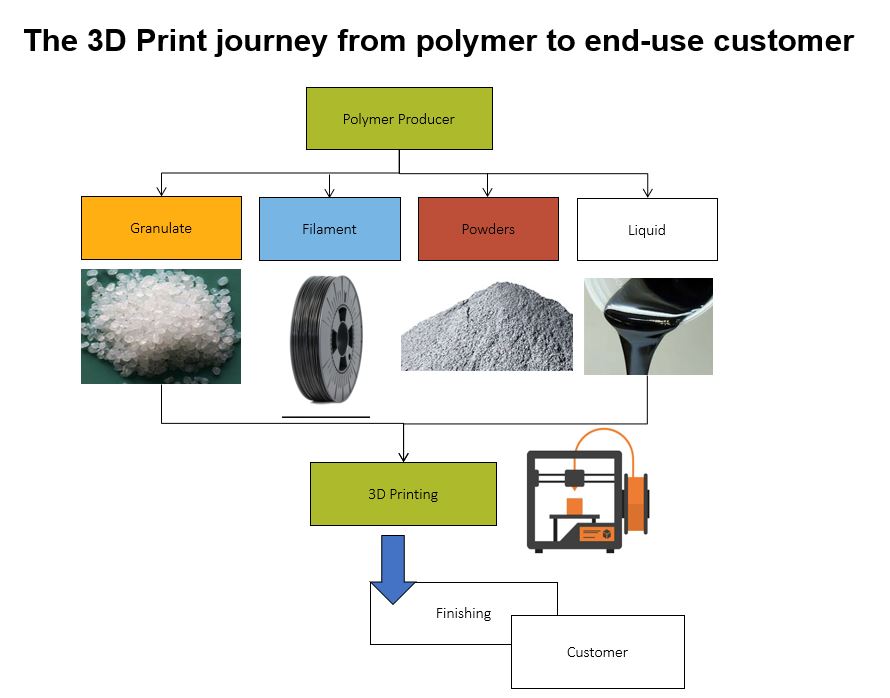

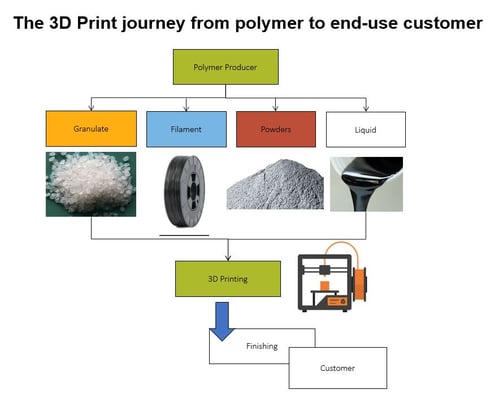

Many 3D printing applications are a collaboration between polymer producer, filament or powder producer, printer manufacturer, and user of the component or part. Some printers and polymer producers work on an ‘open source’ basis.

Current market volumes for polymers (excluding photopolymers) are reportedly less than 10 ktpa but with demand growth predicted at more than 20% per year. Prices are not transparent, as much polymer is transferred through supply chains still in development. However, powders for SLS can be $100 -200/kg. For FFF 3D printing, 3D printer filament prices – such as PLA – can cost around $20 to $50 per kilogram, with specialized engineering or support filaments rising to $60 to $120/kg. These are prices – as of late 2021 – from Germany-based 3D print solution supplier Ultimaker.

Engineering polymer producers have participated in this relatively new market segment to gain experience and explore its potential so that businesses are prepared to target future larger markets that they believe will open up.

Solely Focused on the Future

The Futurecraft athletic shoes – developed collaboratively by adidas and Silicon Valley startup Carbon – demonstrate 3D printing's capacity to deliver new, unique, complex structured products.

The partnership delivered a lattice-design midsole made out of a blend of UV-curable resin and polyurethane. Using a method Carbon describes as Digital Light Synthesis, the blend is cross-linked and solidified by UV light and oxygen.

Carbon describes its epoxy resin material EPX 82 as comparable to a 20% glass-filled thermoplastic. The company's latest material offering EPX 86FR is a flame retardant cross-linked aromatic epoxy/amine that was launched in February 2022.

Last month, UK aerospace industry supplier Brookhouse Aerospace announced its purchase of a Stratasys Fortus 450mc 3D print station. This equipment processes materials including carbon fiber and the FDM nylon 12 used in aerospace and automotive sectors (and others). Polyetherketoneketone (PEKK) printing – for oral implants like crowns and bridges for the dental industry for example – can also be completed on the machine.

Covid-19 Response Revolutionary

Building on this lattice form some years later, Carbon partnered with Reliance Medical to create a 3D-printed lattice nasal swab for detecting Covid-19, and personal protective equipment (PPE). Based on the speed at which Carbon was able to develop its Covid-19 offerings – the swab and personal protection equipment – 3D printing is indeed now meeting its aspirations of a mass manufacturing revolution.

The quick, cheap, efficient, and reliable response companies like Carbon made to the global pandemic effort could prove the breakthrough platform that takes 3D printing techniques to the next level.2 Palo Alto-based information technology company HP Inc mobilized its global R&D centers to provide over 1,000 3D printed items including PPE to local hospitals across Europe and the US in the first months of the pandemic.

Energy Saving

Additive manufacturing technology is also a zero – or low–waste technology. In SLS printing, the unsintered powder can be used over and over again. Its sustainability is enhanced by the elimination of specialist process equipment. A standard 3D printer interacting with standardized computer-aided design software can be used in any and every location globally.

A study published in the ACS Journal of Sustainable Chemical Engineering investigated energy usage levels for printing ABS and PLA parts. In comparing conventional large-scale molding methods with open-source additive manufacturing techniques in low-labor cost countries, the team's life cycle analysis showed that additive manufacturing reduced energy demand by 41–64%, and more when solar-powered. 3

There is little doubt that additive manufacturing – in line with composites manufacturing which we covered in a blog earlier this year – is game-changing for the delivery of unique, complex structured products. It harnesses a range of materials – and materials' properties – including lightweight materials that maintain strength. That is a paradigm-shifting development for sustainable travel as it reduces fuel consumption in use and supply chain transportation – all of which make products more sustainable.

The reductions to inventory and the need for tooling that conventional processes require make it an attractive efficiency-driving choice for manufacturers.

Additive manufacturing can contribute to more sustainable business models by eliminating the need for offshore production plants has the potential to disrupt the global marketplace. However, waste reduction due to its inherent efficiencies coupled with its potential to foster localized manufacturing hubs renders it an increasingly attractive business proposition.

Subscribe to our blog to have market insights delivered to your inbox.

References

1. Ligon, S et al. Chem. Rev., 2017 DOI: 10.1021/acs.chemrev.7b00074

2. Oladapo, B. et al. Master Chem Phys., 2021 DOI: 10.1016/j.matchemphys.2020.123943

3. Kreiger, M. and Pearce, J., ACS Sustainable Chem. Eng., 2013 DOI: 10.1021/sc400093k