5 min read

Can White Hydrogen Answer Humanity’s Fundamental Energy Needs?

Jane Denny

:

Nov 15, 2023 11:50:15 AM

Jane Denny

:

Nov 15, 2023 11:50:15 AM

The chemical industry, the high-volume sector of the industry in particular, pivots on the conversion of fairly inert carbonaceous matter into chemically active materials.

This output is achieved through the application and absorption of energy. But that very energy also comes from carbonaceous matter via combustion, which releases carbon dioxide.

Much of today’s research effort is directed at finding alternative ways of providing that energy input. That is the objective of the endeavors to move to sustainable methods of chemicals production. The main alternative energy source under exploration is renewable hydrogen.

In fact, the chemical industry already uses large volumes of hydrogen. Nitrogen-based fertilizer production is one example. However, that so-called grey hydrogen emits carbon dioxide (CO2) into the environment in large volumes. Typically, for each ton of hydrogen produced using natural gas as the starting material, 7.3 tons of CO2 is emitted.

The amount increases somewhat when the feedstock is petroleum, and a great deal more with coal as the starting material. With world production of hydrogen at around 90 million tons annually, it is estimated that around 900 million tons of CO2 is co-produced. That end estimate for CO2 takes the accompanying generation of CO2 from the energy consumed into account.

Based on a recent (high-end) US natural gas price, the total cost of hydrogen production is $1250/ton (assuming no emissions penalty).

Cost Comparison: Hydrogen Production and Natural Gas

Taking the price for natural gas as $5/mmBtu ($4.75/gigajoule or $17/MWh)—which is at the high-end of recent US pricest—the total cost of hydrogen production is $1250/ton based on there being no penalty for the CO2 emitted.

In Europe today, the cost of natural gas is around $14.7/mmBtu ($13.9/gigajoule or $50/MWh). This makes the cost of hydrogen production $3675/ton before any carbon debits.

There are however, growing pressures for such penalties to be applied. Such a move potentially increases costs by 50% or more, depending on the regime where production takes place.

Capturing and sequestering the CO2 avoids such charges, and delivers what is regarded a sustainable product, blue hydrogen. The early state of the technology available at present underpins a total cost considerably higher than grey hydrogen.

Splitting Water with Electricity

Hydrogen generated without the co-production of CO2 is called green hydrogen. It can be produced by electrolysis of water, at a cost that is mainly determined by the cost of the electricity used. The production of one metric ton of hydrogen by electrolysis requires 53 MWh (190 GJ) of electrical energy.

Such energy must be renewable. Therefore, it should be generated from solar panels or wind turbines (or possibly a nuclear power station). The most efficient of these renewable sources carry production costs of around $70/MWh. This makes the power cost alone $3710 per ton of blue hydrogen, leading to a total cost of around $5000/ton.

Despite the high cost of these types of hydrogen—and with only blue hydrogen having a long-term future—worldwide there are numerous initiatives already in place to use hydrogen as a transport fuel or a chemical feedstock. Based on the expectation that costs will reduce as producers achieve economies of scale and develop better technology, the initial expenses are justified. And with penalties for CO2 emissions destined only to increase, hydrogen power is seen as a solid gamble.

A Well-founded Discovery

With this outlook, the recent discovery of underground sources of hydrogen has elicited widespread interest, to the point that it is already being called white hydrogen.

White hydrogen’s existence was indicated thanks to a water well dug in the village of Bourakébougou, Mali, West Africa in the 1980s. It is said that one of the drillers leaned over the side of the well with a cigarette in hand, triggering an explosion with flames. The well was closed and abandoned.

Just over a decade ago, a local entrepreneur reopened the well and installed a car engine modified to run on hydrogen. When connected to a generator it was possible to provide electricity to the village for several years. It is now being replaced by fuel cell power generation.

The discovery of up to 250 million tons of hydrogen within a deposit in France recently triggered widespread searches for more white hydrogen sources.

Fortuitous Find: Underground Hydrogen Source

Geologists had noted the presence of hydrogen in gases coming from drilling for natural gas or petroleum for many years, but it was regarded as of no interest. Then, in May 2022, a large deposit of natural hydrogen was accidentally discovered in the Lorraine region of France.

While testing methane levels in the soil using a special probe, a research team from the University of Lorraine, the CNRS (France’s National Centre for Scientific Research) and energy producer La Française de l'Energie found a source of hydrogen.

At first—a couple of hundred meters down—the probe indicated low concentrations but the deeper it went, the higher the hydrogen concentration. At 1100 meters the concentration was 14%. By delving just 150 meters more, the team found a 20% concentration level.

This indicated the presence of a large reservoir of hydrogen beneath. Analysis has indicated the volume of hydrogen within the deposit could be as much as 250 million tons. The discovery triggered widespread searches worldwide for more possible sources of white hydrogen.

Hydrogen's Viability as a Fuel

The cost of finding and drilling for white hydrogen, which is mostly of high purity, is estimated at around $1000/ton, but possibly as low as $500/ton. At the lower end, this would make it competitive with natural gas as a heating fuel, particularly if natural gas has carbon penalties applied.

Questions abound: Can we introduce hydrogen to the natural gas distribution network? With hydrogen molecules being much smaller than methane, could leaks into the atmosphere occur?

However, use as a fuel would be a waste of a resource that has the potential for many industrial applications, such as steel smelting, fertilizer production and chemicals manufacture. These industries could be rescued from the threat of imposition of heavy carbon emission penalties if white hydrogen could become readily available.

There are many questions still to be answered. Can hydrogen be introduced into the natural gas distribution network? There is anxiety that leaks of hydrogen to the atmosphere could occur, with hydrogen molecules being much smaller than methane. There is also uncertainty as to whether piping and storage tanks will be corroded by contact with hydrogen. There are greater risks of explosion with hydrogen than with methane.

Another question is how large and how widespread the underground deposits are, and how soon they might become depleted. Certainly, exploration and drilling activity is happening at many locations in the world. Deposits have been discovered in Australia, eastern Europe, France, Oman, Spain and the US, while drilling is expanding in Mali.

Uncovering Hydrogen Reserves Worldwide

Upon examining South Australia state archives and finding evidence of very high concentrations of hydrogen in a number of boreholes drilled in the 1920s, Brisbane-based Gold Hydrogen began drilling in the Yorke Peninsula. It transpired that the initial prospectors—interested in hydrocarbon fossil fuels only—had abandoned the project.

In the US, a Denver-based white hydrogen start-up named Koloma has secured $91 million from investors. And Natural Hydrogen Energy—also based in Denver—completed an exploratory hydrogen borehole in Nebraska in 2019 and has plans for new wells.

In northeast Spain, exploration company Helios Aragón is reported to have located a reservoir of over one million tons of hydrogen, which it aims to start drilling in 2024. Helios Aragon was founded on old but promising data: a “show” of 25% hydrogen in the Monzon-1 well, drilled in 1963 to a depth of 3.7 kilometres by the National Petroleum Company of Aragon.

How Did White Hydrogen Originate?

Even if many deposits are found, how long might it take before they become depleted? That question is bound up with that of how the hydrogen deposits were formed in the first place.

One theory is that the deposits are the small remainders from the creation of the earth a few billions of years ago. In that case, the reserves might be limited and run out one day.

Another theory is that radioactive elements in rocks emit radiation that can split water. The process is slow, so it would take eons to restore depleted reserves.

But the preferred explanation of the source is that hydrogen is being continuously generated in cratons, the ancient cores of continents. Trapped within them are bands of iron-rich rock, called greenstone belts or olivine, which are the remnants of ocean crust that got squeezed between the cratons in ancient continental collisions.

Where olivine is buried deep enough to be subjected to temperatures of 200-350°C, while being exposed to water percolating from the surface, a reaction can take place. The iron in the olivine, which is in the Fe(II) oxidation state, moves to the Fe(III) state, at the same time reducing the water to hydrogen.

The olivine morphs into serpentinite and magnetite (Fe3O4), a process called "serpentization". This process is already well known from studies of the mid-ocean "smokers" which belch gas and metals out of tall chimneys formed as molten lava comes into contact with the near-freezing water.

If this is the process whereby hydrogen is generated, it would appear that the supply of hydrogen is continuously replenished, avoiding the dangers of depletion. Indeed, the generation of hydrogen might even be stimulated by injecting water into the olivine deposits. Human ingenuity knows no bounds!

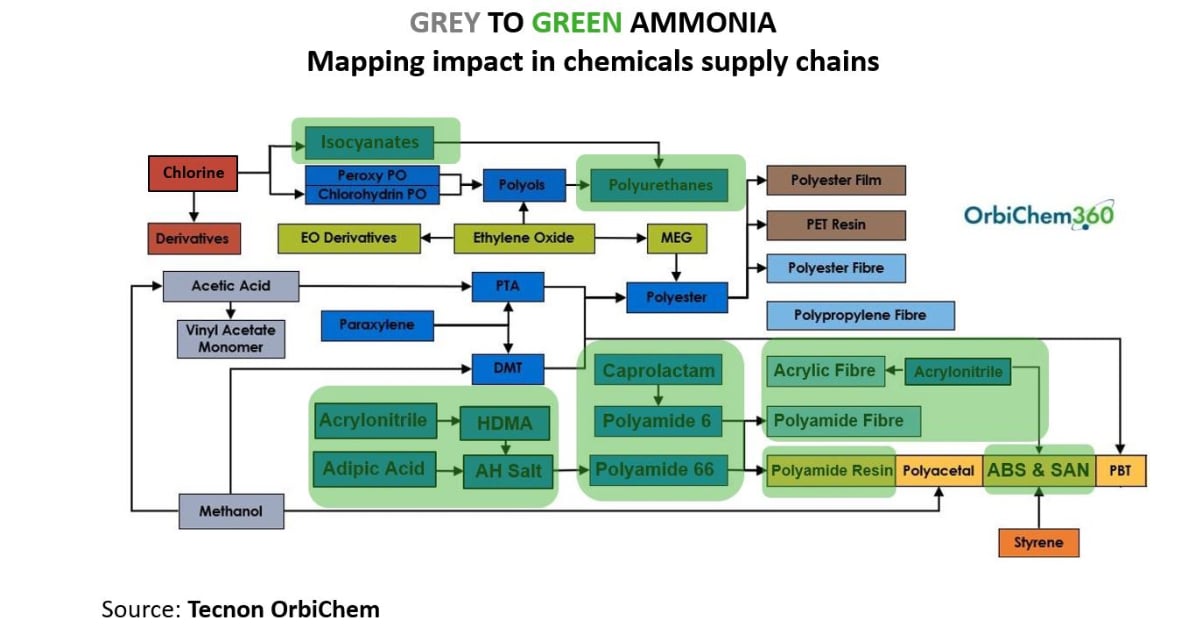

Find out how renewable hydrogen fits into a green ammonia future for the chemicals sector in our blog post Green Ammonia Chemical Feedstocks: A Promising Future.