1,4 Butanediol, commonly known as BDO, is a chemical intermediate that was originally obtained though reaction of acetylene with formaldehyde, known as the Reppe process. Other popular technologies use butane/maleic anhydride, propylene oxide and butadiene as feedstocks. In recent years bio-based BDO production technology has been developed as an alternative to the traditional raw materials. BDO is used in polyurethane production via tetrahydrofuran (THF) which is used to make polytetramethylene ether glycol (PTMEG) which is used in spandex production. Its other major downstream market is polybutadiene terephthalate (PBT), a thermoplastic polyester used in the production of engineering materials.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Acetone is primarily used as a chemical intermediate and as a solvent. As a chemical intermediate acetone is used to produce bisphenol A, methyl methacrylate (MMA) and MIBK, as well as diacetone alcohol (DAA) and hexylene glycol. As a solvent, acetone is used for acetylene storage, varnishes, lacquers, printing inks, adhesives and cellulose resins.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Adipic acid is a chemical intermediate used in the production of nylon 66 resin and nylon 66 fibre or in polyol and polyurethane production. By far the largest demand is in nylon 66 production for both fibre and resin, whilst the remainder is consumed in non-nylon applications including polyurethanes. It is produced by oxidising cyclohexane to cyclohexanol and cyclohexanone, generally with a catalyst, and then the products are reacted with nitric acid to form adipic acid.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Epichlorohydrin (ECH) is a chlor-epoxide that is essentially based on the reaction of chlorine with propylene through a number of reaction steps: it may be regarded as being similar to propylene oxide with the addition of a reactive chlorine site. The two routes to ECH are via allyl chloride and allyl alcohol: allyl chloride is by far the main route. ECH is used mainly (70%) in the production of epoxy resins and also in the manufacture of synthetic glycerine and cationic polymers and starches.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Ethanol, also known as ethyl alcohol, has the chemical formula CH3CH2OH. Ethanol is a versatile solvent, miscible with water and with many organic solvents. Ethanol is also used to produce vinegar, alcoholic beverages and has medical applications as an antiseptic and a component of drug formulas. Ethanol for fuel is by far the most important end use segment. Ethanol is produced both as a petrochemical, through the hydration of ethylene and, via biological processes, by fermentation of plant materials (e.g. barley, rice, corn and sugarcane).

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Ethylene is one of the major chemical building blocks and the largest of the olefins (by sales volume). Its main use is as the monomer for various forms of polyethylene. Ethylene is produced by steam cracking, predominantly of naphtha in Europe and Asia, and of ethane in North America and the Middle East. Co-products are propylene and a C4 stream containing butadiene. Ethylene is also used to produce vinyl acetate and as a co-monomer in other types of resin. Although propylene is growing in importance, the demands of the ethylene market still mainly drive the operation of steam crackers.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

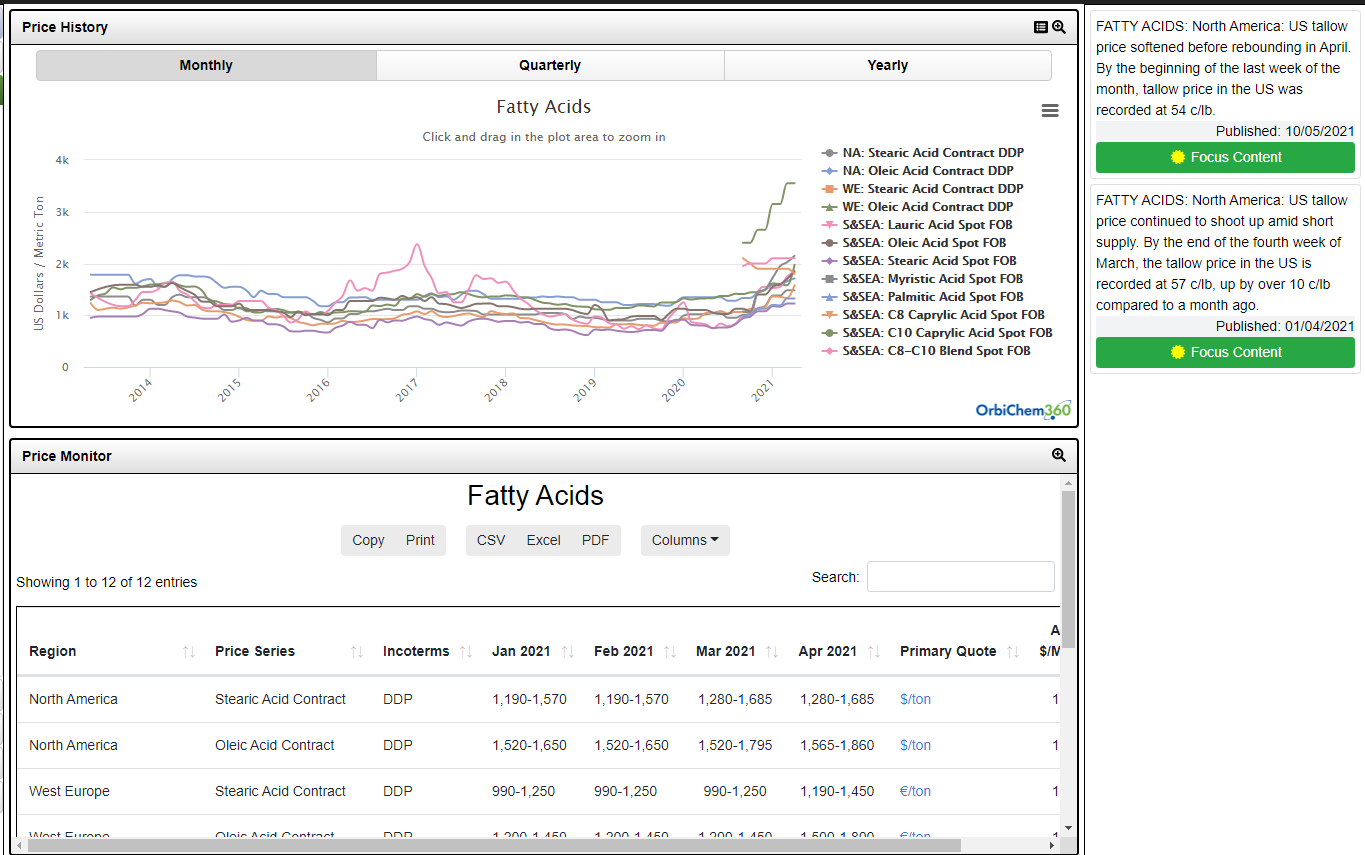

Fatty acid is a carboxylic acid usually derived naturally from animal fats and vegetable oils. Fatty acids commonly exist in combination with glycerol. Hydrolysis is the basic production step for splitting crude glycerol from a mixture of crude fatty acids, which are then separated further into a more specific chain length using fractional distillation. Major end use for fatty acids includes the manufacture of soaps, detergents and surfactants. Other applications, among others, include plasticizers, lubricants, as cosmetic raw material, in food ingredients, and in the manufacture and compounding of natural and synthetic rubbers.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

The majority of fatty alcohols are manufactured by hydrogenation of fatty acids or fatty acid methyl esters. However, they can be produced synthetically using ethylene or n-paraffins for feedstock. Fatty alcohols are then further subjected to various processes such as sulfation, ethoxylation, amination, and phosphatization. Fatty alcohol can be fractionated to separate the C8-C10 fraction known as plasticizer range alcohol, and the C12-C18 known as the detergent range alcohol. The greatest application of fatty alcohol is in the manufacture of surfactants for laundry detergent products, shampoos, dishwashing liquids and cleaners. The C12-C14 alcohol finds application as lubricant additives and in the formulation of bearing and hydraulic oils.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Glycerine, also called glycerol, is a tribasic alcohol mostly occuring naturally with fatty acid in the form of triglycerides. It can be produced as a by-product in soap and fatty acid manufacture or as a by-product of biodiesel production via the transesterification of fats and oils into methyl esters. Glycerol can also be manufactured synthetically by various routes from propylene. Uses of glycerol are numerous ranging from cosmetics and personal care, to food products and industrial applications such as in plasticizers, lubricants, explosives, pharmaceutical, resins and in polyurethane manufacture. Glycerol is increasingly being developed and used as a building block in the manufacture of intermediates such as epichlorohydrin, propylene glycol, acrylic acid, among others.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Hydrogen is one of the key starting materials used in the chemical industry. It is a fundamental building block for the manufacture of ammonia, and hence fertilizers, and methanol, used in the manufacture of many polymers. It is also used in the refining of oil, for example, in reforming, one of the processes for obtaining high-grade petrol and in removing sulphur compounds from petroleum which would otherwise poison the catalytic converters fitted to cars. Hydrogen is potentially an environmentally attractive fuel for the future. When it burns to produce energy, the only product is water.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Methanol is one of the world’s major commodity chemicals and a feedstock for chemicals used in many common consumer products. Methanol is made from natural gas and production sites are predominantly located where there are large quantities of cheap gas – often in remote areas and/or associated with oil production. It is easy to transport and is moved around the world in large volumes. Its major derivatives are formaldehyde, acetic acid, MTBE, methyl methacrylate and a variety of chemical intermediates. It also has a whole host of minor uses, including solvents, which are sometimes region-or even country-specific.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Propylene glycol is a chemical intermediate obtained by hydration of propylene oxide. Di- and Tripropylene glycols, as well as small quantities of higher glycols, are also produced in the reaction. End markets are many and varied, one of the major uses being unsaturated polyester resins, which are used in surface coatings and glass fibre reinforced resins. Another very seasonal segment is in antifreeze and aircraft de-icing applications. USP grade MPG is used as a humectant in food and cosmetic applications, as a solvent for colouring and flavouring agents, and in various pharmaceutical uses.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Monoethylene glycol (MEG) is a chemical intermediate produced from ethylene oxide (EO). Its main use is as a feedstock for polyester condensate in conjunction with PTA and DMT. The other main use is in antifreeze/coolant blends. Most production processes give by-products di-ethylene glycol (DEG) and tri-ethylene glycol (TEG).

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

n-Butanol/iso-butanol (often in roughly a 4:1 ratio) are usually produced in a plant with 2-ethylhexanol by applying the oxo reaction to propylene to produce butyraldehyde. n-Butanol is the more commercially important product, significant outlets are acrylates, glycol ethers and acetates.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Paraxylene is the main feedstock for purified terephthalic acid (PTA) and dimethyl terephthalate (DMT). These intermediates in turn are used to make polyethylene terephthalate (PET) for use in fibres for textiles, bottles for soft drinks and water, as well as some film. Paraxylene is separated from a mixed xylene stream, which also has value as a source of gasoline blending components. Alternative routes to paraxylene include toluene disproportionation, which yields benzene as a co-product. It is a colourless, flammable liquid with a sweet odour.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Pine chemicals are co-products derived from the Kraft pulping process used by the pulp and paper industry. Crude Tall Oil (CTO) can be further distilled into other pine chemicals such as heads, pitch, distilled tall oil (DTO), tall oil fatty acid (TOFA), tall oil rosin ester (TORE) and tall oil rosin (TOR). These are refined and upgraded into a wide range of bio-based specialty chemicals.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polyethylene terephthalate (PET) packaging resin is produced by reacting monoethylene glycol (MEG) with either terephthalic acid (TPA) or dimethyl terephthalate (DMT). The resultant monomer is heated under low vacuum pressure to form long chains of PET polymer. It is a clear, strong and lightweight packaging material that can be extruded or moulded into bottles and containers for drinks, food and household products. Post-consumer PET bottles are increasingly recycled to produce polyester staple fibre, packaging and bottles.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polybutylene succinate (PBS) is a biodegradable plastic used in applications such as packaging for food and consumer electronics, tableware, agriculture mulch films and civil engineering materials. Due to its aliphatic nature, the hydrolysable ester bonds within its structure are relatively accessible for microbial degradation. PBS homopolymer is made from the condensation of succinic acid and 1,4-butanediol.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polyamide (Nylon) resins include a range of polymerisation polymers, PA6, PA11, and PA12, as well as several condensation polymers, such as PA66, PA610, and PA46. PA6 is a polymer of caprolactam. PA66 is produced by condensation polymerisation of adipic acid and HMDA. Together they account for a large majority of the engineering resin volume produced globally. PA6 is easier to injection mould, cast, or film, while PA66 has superior temperature performance and tensile strength in automotive applications and is usually more expensive. The Bio-Materials coverage typically include polyamides PA410, PA5X, PA610, PA10X, PA11 that use bio-based feedstock as well as polyamides based on mass balance systems.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polyhydroxyalkanoate (PHA)

Polyhydroxyalkanoates or PHAs are linear polyesters that can be regarded as self-condensation polymers of molecules containing both a hydroxyl and a carboxylic group. The main such monomers are 3-hydroxybutyric acid, which gives rise to poly(3-hydroxybutyrate) or P3HB, and 3-hydroxyvaleric acid, which gives rise to poly(3-hydoxyvalerate) or P3VB. The most extensively studied member of the PHAs is P3HB and it is often designated simply as PHB. There are many other hydroxyalkanoic isomers (it is said there are more than 150), which can combine to form PHAs of widely differing properties.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polylactic acid (PLA) is a thermoplastic aliphatic polyester derived from renewable resources such as corn, sugarcane or cassava. PLA homopolymers have a glass-transition and a melting point of about 55°C and 175°C, respectively. PLA is one of the most common bioplastics in use today. PLA is usually produced by chemical synthesis from bio-derived lactic acid monomers.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polyester polyols are produced by the condensation of a glycol and a dicarboxylic acid or acid derivative. The three general types of polyester polyols are manufactured from aliphatic diacids, aromatic diacids or caprolactone. Raw materials include phthalic anhydride and adipic acid. The functionality, structure and molecular weight of the polyester polyol differ depending on the type of polyurethane application. In some applications, polyester polyols compete with polyether polyols. Uses include rigid foam for use in the construction/insulation market and performance coatings, elastomers and flexible foams.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Polyether polyols together with isocyanates are essential precursors in the manufacture of polyurethanes. Although the highly reactive isocyanate group is the unique feature of polyurethane technology, it is the polyols that in large part determine the properties of the final polyurethane polymer. Polyether polyols are hydroxyl-functional polymers usually made from the reaction of PO and or EO with an initiator. There are various kinds of polyols, but polyether polyols account for the lion’s share of the polyol market. Rigid polyols are reacted with MDI to make rigid foam, and flexible polyols are reacted with TDI to make flexible foam.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Purified terephthalic acid (PTA)

Purified terephthalic acid (PTA) is an intermediate in polyester production along with monoethylene glycol (MEG). PTA accounts for two thirds of the polyester molecule. It is made via the oxidation of paraxylene, and the final product is in the form of white flakes. Certain suppliers make medium-quality terephthalic acid (MTA) and qualified terephthalic acid (QTA) available, but the overwhelming bulk of polyester fibre and resin production is based on PTA. Dimethyl terephthalate (DMT) competes with PTA as a polyester intermediate but all new polyester production is based on PTA feedstock.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Sebacic acid is a dicarboxylic acid with the structure (HOOC)(CH2)8(COOH). It has a melting point of 131-134°C and is supplied as a white granule or powdered crystal. Sebacic acid is the diacid monomer used for the manufacture of nylon 6,10, a plastic widely used in everyday household items such as toothbrush bristles and fishing line. The sebacates of various oxo and straight-chain alcohols are important plasticisers. Moreover, sebacic esters are used as components of lubricating oils and as diluents. Other applications of sebacic acid include use as an intermediate for aromatics, antiseptics and painting materials, as well as use as a corrosion inhibitor in metalworking fluids. Sebacic acid is primarily produced from castor oil, which is obtained from castor beans through mechanical pressing.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Succinic acid is a dicarboxylic acid currently produced either from conversion of petroleum-derived maleic anhydride or from bacterial fermentation of carbohydrates. Historically, the high cost of producing succinic acid from petroleum feedstock limited its use to a narrow range of applications such as pharmaceuticals and food ingredients. The growing availability of biobased succinic acid is opening applications such as plasticizers, polyurethanes, personal care products, deicing solutions, resins and coatings, lubricants, and as a building block for a number of chemical intermediates. Succinic acid can be used to produce 1,4 butanediol (BDO), tetrahydrofuran (THF) and polybutylene succinate (PBS) biodegradable resins.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Viscose fibre is spun from cellulose. Viscose filament is mainly used in lining fabrics, dresses and blouses and velvets but also has industrial uses in tyre cord and other products. Viscose staple is spun into viscose and viscose blend yarns which are used in clothing and furnishings. It is also widely used in various non woven products. Recently staple use in non-wovens has been boosted by the rapid growth of non-woven wipes products because of its softness and absorbency.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Crude Palm Oil is a widely traded vegetable oil comparable to soybean oil. It is obtained from the fruit of the oil palm tree through pressure extraction as well as solvent extraction. It contains very high amount of saturated fats like coconut oil. Triglyceride content is 94-97%. Major producers of crude palm oil include Malaysia and Indonesia. It is mostly used as cooking oil. Industrial uses include biodiesel and production of soaps and fatty acids.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Rapeseed Oil for food use is obtained by pressure extraction from rapeseed oilseed. For industrial use, rapeseed oil is recovered using solvent extraction from the residues of the pressure extraction. High erucic rapeseed contains at least 45% of erucic acid in the oil. Primary market for these high erucic oils is production of erucamide, which is used in the manufacture of plastic films. Another industrial use of rapeseed is the production of biofuels and oleochemicals.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

RBD Palm Oil is refined, bleached and deodorized palm oil obtained from refining crude palm oil. It is used as frying oil for food industries and also in the manufacture of margarine, shortening, other dairy products and soap. See further definition of Crude Palm Oil.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

RBD Palm Olein is refined, bleached and deodorized liquid component of a fractionated palm oil. The main component of olein is oleic acid. Oleines and its derivatives are used in the formulation of cosmetics, detergents and lubricants, and in the production of intermediates such as surfactants, solvents and fine chemicals.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

RBD Palm Stearine is refined, bleached and deodorized solid component of a fractionated refined palm oil. Technically, stearine is a mixture of stearic and palmitic acid although the main component is stearic acid. Stearines are used in the production of candles, soaps, rubber compounds, food ingredients, fabric softeners and cosmetics. Long-chain stearines contain a proportion of higher chain acids; this enhances important properties such as lubricity, oil solubility and water-resistance.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Palm Fatty Acid Distillate

Palm Fatty Distillate (PFAD) is a lower-value by-product from refining crude palm oil. It is used in soap industries, animal feed industries and as raw materials for oleochemical industries. It is also considered a potential raw material for biodiesel production. The main component of of PFAD is free fatty acids, which are oleic, stearic and palmitic. Because of its impurities, its quality is less stable and it needs short storage.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Palm Kernel Oil (PKO) is an edible plant oil derived from the kernel of the oil palm tree Elaeis guineensis. Currently, palm oil and palm kernel oil are chiefly used in the manufacture of foodstuff. Only around 5% of it is processed into biofuel, and the remainder of global palm oil production (ca. 10-22%) is used in industry, such as in the production of detergents and cosmetics.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Soybean Oil is a widely traded vegetable oil across the world and is used mainly for food. It is also used in biodiesel production. Crude soybean oil consist typically of 96% triglycerides, 2% phospholipids, 1.6% unsaponifiables, and 0.5% free fatty acids. The fatty acid composition of soybean oil depends on the variety and growing conditions. Unsaturated fatty acids account for over 80% in soybean oil. Soybean oil is obtained by solvent extraction from soybeans.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Tallow is obtained from animal tissue containing fat through a process called rendering. Like vegetable oil, tallow is a triglyceride. For industrial applications, tallow can be used to produce biodiesel, soap and fatty acids. The US and European oleochemical industry are big consumers of industrial tallow product.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Coconut Oil is extracted from the kernel or meat of matured coconuts. It is used in a variety of applications ranging from food use to industrial use such as manufacture of soap, fatty acids and biodiesel. Lauric acid, a 12-carbon chain fatty acid, is often removed during fractionation of coconut oil because of its high value as industrial fatty acid product.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Corn is the largest component of global coarse grain trade and is processed into a multitude of applications such as for food via dry milling process and industrial products via wet milling process that include starch, sweeteners, corn oil, beverage, industrial alcohol and fuel ethanol. Due to technology advances, industrial use of corn has constantly been growing especially through the use of fermentation technology in the production of chemicals.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Corn Starch is the carbohydrate polymer accounting for about 80% of the total weight of a corn kernel. It is produced through a corn wet milling process. Many industrial products are increasingly being synthesized from starch or cellulosic feedstocks such as in the production of biodegradable plastics because of the excellent chemical composition of starch. Other industrial applications include super absorbent polymers (SAPs), adhesives and binders, as flocculating agents, anticaking agents, and as ingredients in personal care products.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

Dextrose is a simple sugar also called D-glucose obtained from starch through hydrolysis. The corn industry produces many types of syrups that are identified by reference to the dextrose equivalence (DE) value. Crystalline dextrose is quite pure and finds many food and industrial uses. Liquid dextrose applications are generally used for fermentation and in the production of enzymes.

-

Market Analysis

Market Analysis

-

Prices

Prices

-

Trade Data

Trade Data

-

Market Summary

Market Summary

-

Price Forecasts

Price Forecasts

-

Supply/Demand

Supply/Demand

-

Single Client Projects

Single Client Projects

ChemFocus

ChemFocus ChemFacts

ChemFacts ChemForesight

ChemForesight ChemExpert (includes ChemFocus modules)

ChemExpert (includes ChemFocus modules) Consulting

Consulting